Tube Side Exchangers - An Undisputed Citizen in the Whole Process of Heat Transfer for Industries

In the realm of heat transfer, Zhuoli Tube Side Exchangers are necessary players for multiple industries. Since decades these Tube-in-tube heat exchanger are considered as a perfect sustainable and trustworthy solution to transfer heat from one fluid flow stream to another efficiently.

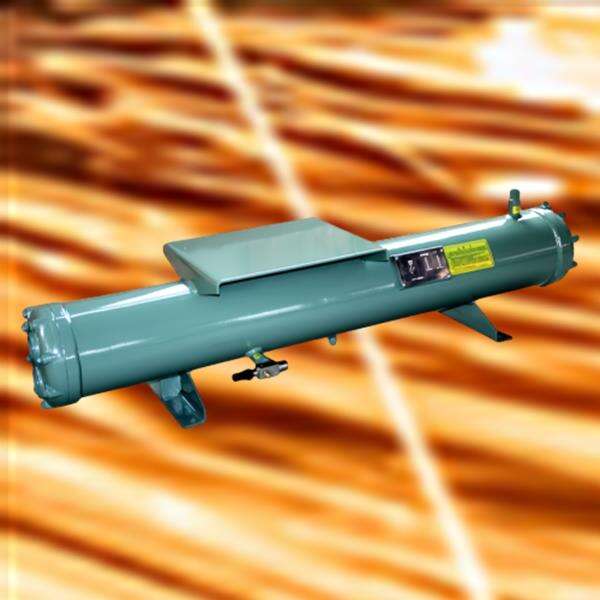

Tube Side Exchangers are very general type of heat exchanger and typical operating pressure is 40 Kg/cm2; however HT Assemblies have been designed for higher pressures. Their robust design and top-notch elements are bound to guarantee longevity and reliability, but their incredible heat-transfer capacity will virtually make them products that help you save on your energy bills. These Zhuoli machines are durable and can work long hours even at high pressures or temperatures, so that they make it a real asset for sectors which require stable and safe production processes. Moreover, the Spiral tube heat exchanger compact design makes them easy to fit and interfere with the few requirements for installation, maintenance or cleaning.

The most common reason for the design of Zhuoli Tube Side Exchangers is that by comparison to other designs have very good invention. These include both an inner core and a tube contained within the surrounding casing. Heat generated in the inner fluid is conducted through a wall of tube to an outer flow casing. It does so by forcing all the fluid to move in smooth and predictable manner, Tube side heat exchanger helps create a well-organized state of flow that optimizes heat transfer then.

Tube side Exchangers are manufacturer dependent and may vary in geometry depending on the manufacturers at different levels of configurations for Chemical, Food, Pharmaceutical or Power Generation applications. They are mainly used in various processes which include cooling and heating of fluids, drying processes or heat recovery. To achieve this, the outlet(s) of fluid compounds require to flow in U-shaped tube condenser and also outer shell. The key components to look for include the fluid flow control valves and pressure gauges that help keep an eye on how well the heat exchanger is functioning.

Tube Side Exchangers need to service regularly as it is important to prevent optimal operation. This mainly consists of cleaning, maintenance tasks and pressure-temperature-watching. It requires a skilled team of engineers and technicians to service as well-maintain it properly. These Tube and shell heat exchanger are manufactured using premium grade of raw materials, thereby guaranteeing a long working life and adherence to world-class quality standards.

With more than 20 years' experience in industry and expertise, we have gained rich knowledge technology in the area of heat exchangers. Our Tube side exchanger team fully comprehends technological developments market needs and provides precise and efficient tailored solutions to make sure that every product is in line with highest standards.

We believe in close cooperation with customers and offer a range of services. Our expert team be there to guide customers through every step from need analysis to design of a solution and support after sales, create maximum Tube side exchanger for each client.

We are committed in our ongoing innovation, research development and Tube side exchanger the performance our products and customer service. Our R and D department at the forefront of innovation industry, creating breakthrough technology and products address changing customer needs and help drive industry progress.

We employ most advanced manufacturing {keyword}} equipment, to ensure excellence at every stage. products are developed to exceed highest standards in endurance, reliability performance.