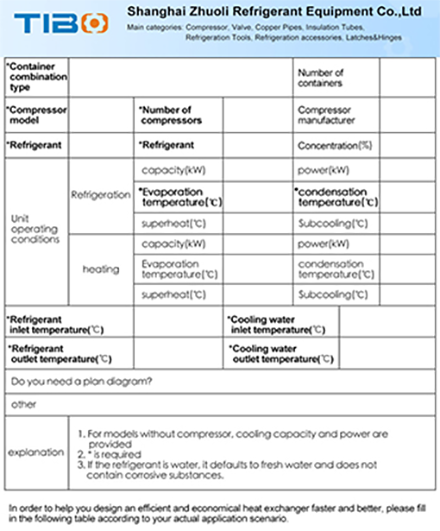

(1)Product Information

Our Products are manufactured in accordance with National standards such as GB150-1998, GB151-1999and JB/T4750-2003...

(2)Safety Information

Unless otherwise provided, the refrigerant assumed is R22. Should you requirements differ from those stated in this brochure, please contactour technical team: +86(25)5621 0177

Please ensure that water passing through the heat exchangers have been suitably filtered and purified...

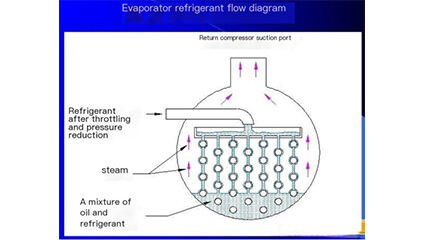

The four components of the refrigeration system are compressor, evaporator, condenser and throttling device. The function of evaporator is to absorb the heat of refrigerant through the evaporation (boiling) of refrigerant, so as to achieve the purpose of refrigeration. There are many types of evaporators. The following mainly introduces the working principle and structural characteristics of several common evaporators.

PU Gloves" >

PU Gloves" > PU Gloves" >

PU Gloves" > PU Gloves" >

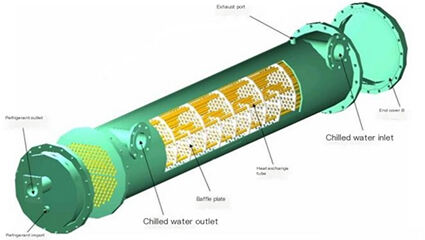

PU Gloves" >The refrigerant passes through the heat exchange tube and runs outside the heat exchange tube carrying the refrigerant, and the heat transfer efficiency of this type of heat exchanger is relatively low. Its advantages: easy to return oil, control is relatively simple, and the refrigerant charging amount is about 1/2 ~ 1/3 of the full liquid unit charging amount.

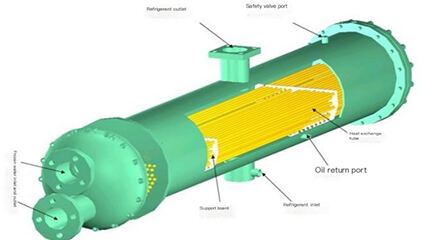

It passes through the heat exchange tube with refrigerant, and the refrigerant completely immerses the heat exchange tube, absorbs heat and evaporates outside the heat exchange tube. There are many needle-shaped holes on the outer surface of the heat exchange tube, and spiral threads on the inner surface of the tube, which strengthen the boiling outside the tube and the heat transfer inside the tube. The heat transfer coefficient is higher than that of the dry evaporator. Its disadvantage refrigerant charging amount is large, the lower part of the evaporator cylinder will accumulate oil, there must be reliable oil return measures.

Falling film evaporator, also known as spray evaporator. The refrigerant of this evaporator is uniformly sprayed from the upper part of the heat exchanger to the heat exchange tube, and the refrigerant forms a thin liquid film on the heat exchange tube. When the refrigerant evaporates, it reduces the static liquid level pressure, thus improving the heat exchange efficiency, and its heat transfer coefficient is higher than that of the full liquid evaporator. Its advantages: the refrigerant charging amount is less than the full liquid evaporator, and has good oil recovery, can effectively avoid the compressor suction with liquid risk.

The main products of the company include shell and tube condensers, dry evaporators, full liquid evaporators, falling film evaporators, seawater evaporators and condensers, vertical and horizontal liquid reservoirs, high exchange oil separators, gas-liquid separators, siphon tanks, and condensation and evaporation machines for Bitzer, Hanbell, Refcomp, Frascold and other compressors........

Our company has rich experience in refrigeration machinery industry. With the advantages of complete varieties and specifications, timely delivery and fast delivery, we provide supporting services for large and medium-sized chillers, ice makers, central air conditioners and refrigeration installation engineering companies. We hope to continue to give full play to the advantages of resource integration and complement the advantages of refrigeration peers around the world to achieve a win-win situation!