Did you ever have a thought as to how your home gets heated up during freezing winters and cooled down in the hot sunlit days? The trick is manifested as a latent piece of apparatus called Zhuoli Heat Exchanger. In this post today, we will get into the heat transfer through Tube Bundle Heat Exchanger; TBHE. Through this article, we will look into what is innovation definition and benefits trends advancements safety operational quality application diversity. Therefore, buckle up and let us travel through this fun path - journey to the world of U-tube heat exchanger.

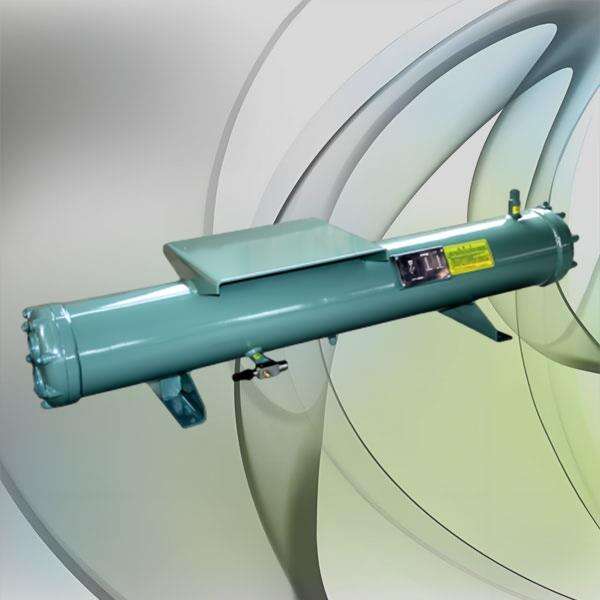

A Tube Bundle Heat Exchanger - A Resource for Efficient Fluid to fluid Heat Transfer These are then connected to external plumbing in such a way that they allow hot water, or refrigerants etc through the various tubes and take heat out of other liquids in a remarkably efficient manner. Employed widely in heating, cooling and air-conditioning systems; the Zhuoli Tube Bundle Heat Exchanger is a life-saver in keeping our indoors cozy.

Pros of conduit lot heater or bundle hotness exchangers

The U-shaped tube condenser has multiple benefits being the ultimate choice in heat transfer world. It features a high heat transfer coefficient, making it possible to produce highly optimized fluid temperatures. Second, it is small in size so that its installation space will be less comparing to others heat exchangers. Third, its construction of less joints and connections reduces the chance of leakage. Even the cleaning and maintenance of it is really easy, so I think that's a great feature. Simply put, the Tube Bundle Heat Exchanger is a high-performance,, compact and easy to use tool.

The increased performance and adaptability of these units have been amongst the substantial advancements in Zhuoli Tube Bundle Heat Exchangers seen over recent years. A prominent innovation is the use of finned tubes, which are equipped with fins on their surfaces to enhance heat transfer properties. Additionally, the use of micro-channel technology has accelerated their miniaturization reducing size and improving efficiency. In addition, by using CAD (computer-aided design) software these machines can be personalized to meet the individual requirements of any project.

Precautions During Working With Tube Bundle Heat Exchanger

When in regards to the equipment that take part at heat exchanger, especially tube bundle return line : a wrong hand can be deadly. These precautions are intended to keep it operating safely. The most important thing is check if both the fluid can be used with the Tube-and-plate heat exchanger in question, and to then monitor their flow rates concurrently. The second condition has something to do with the vicinity in which you intend to install it, preferably a place where no harmful gases get accumulated. Finally, maintenance inspections should be performed to identify any damage needing repairs.

Tube Bundle Heat Exchanger Operation is simple This is where the tubes of exchangers are created, which carries fluids that need to be cooled or heated. There are generally two kinds of arrangements for tubes based on the definite needs, that is counter flow and parallel. When these fluids move through the Tube side heat exchanger, heat is exchanged between two liquids After that, the fluids are returned to their systems where they can be used again.

Quality and serviceability must be kept high for a Tube Bundle Heat Exchanger to perform at its peak. These high-risk devices should be made from materials that can tolerate temperatures and pressures similar to those present in the working environments. Additionally, regular Tube-in-tube heat exchanger maintenance and servicing is essential to avoid breakdowns or faults. Having a planned out service schedule for periodic services helps to identify problems early and deal with them before they can grow.

With more than 20 years of experience and expertise, have gained rich knowledge technology in the industry of heat exchangers. staff of experts is knowledgeable about most recent technological Tube bundle heat exchanger and trends. We offer high-quality efficient solutions to ensure that our products comply with the highest standards.

We use most modern production techniques equipment, guaranteeing excellence each stage. Our products are developed be up to the highest standards durability, performance and {keyword}}.

We believe close cooperation with customers and offer a range of Tube bundle heat exchanger. From needs analysis solution design, after-sales support Our professional team there each step to ensure smooth execution of each project, providing maximum value for our customers.

We're committed to constant Tube bundle heat exchanger, research development and making products more efficient the customer experience. Our R and D team remains at forefront of industry, creating breakthrough technologies products that can meet the demands of customers the changing times and drive industry progress.