The Plate Heat Exchanger: A Great Way to Safely and Efficiently Move Heat

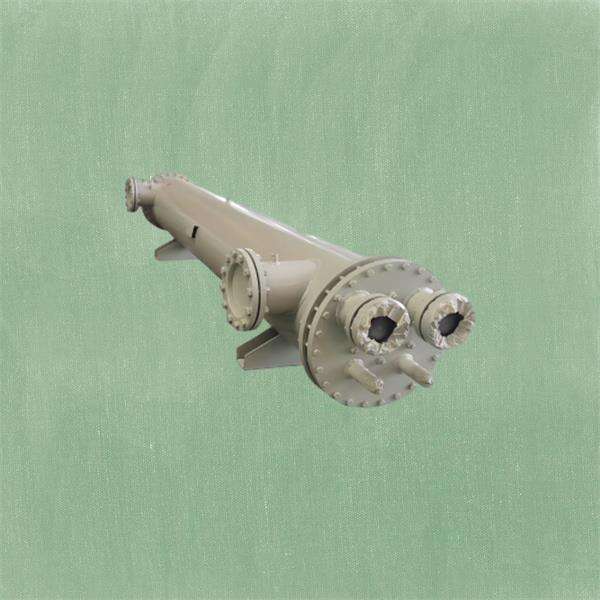

This Zhuoli plate type heat exchanger is particular device that assists in inserting high temperatures from one fluid to more exclusive without making them flow entirely. These are very thin. Wavy plates that have been sealed tightly together within a frame manage this. Being non-power lifting device this innovative machine is immensely getting acclaimed. It is praised all across the industries for its safety. Its user-friendly design and ability to provide unsurpassed performance by transferring heat are also notable.

Pros of the Plate Type Heat Exchanger

It has array of features that differentiate it from other types of heat exchangers. One of its main selling points is high thermal efficiency in a small package size. The intelligent layout offers high area of effect. This occurs even in tiny place. This eventually enhances its heat transfer capabilities. They can also be opened to add or remove plates. The heat exchanger allows variability in the heat transfer capacity. With system maintenance it's a snap. You will be free to take out and clean each plate. This can be done without having disassemble everything.

Innovation in Heat Transfer

There are good reasons for this since plate type heat exchanger is pivotal invention that has reformulated how industry approaches thermal transference. These baffles or corrugated plates inside the device are structurally designed. They implement turbulence in fluid flow to enhance heat transfer process. In other words this innovative design of AIC can also effectively reduce problems like fouling and scaling. Fouling is always a problem for traditional heat exchangers. It decreases their efficiency.

The greatest wealth of the Zhuoli plate type heat exchanger is safety. Sealed plates do not allow for any leakage. This stops fluids from mixing, contaminating one another. This heat exchanger is specifically suited for high-pressure applications. Its design ensures a safe solution useful in many industries.

The plate type heat exchanger by Zhuoli is used in number of sectors such as Chemical, petrochemical Food, Beverage HVAC, Power generation, Pharma. Its very high heat transfer rate per unit length is useful when space is at a premium. It is effective when some heavy-duty cooling needs to be accomplished. The Zhuoli micro heat exchanger still satisfies an important niche. Besides it has proved effective in high-temperature applications.

The Zhuoli plate type heat exchanger is very simple to operate. It is placed in a system that contains channels between the plates. Fluid flows through these channels. One of the two fluids is passed through a thermal flywheel. This is where shell and heat exchanger occurs between the fluid, another with opposing or parallel flow. The amount of heat transfer depends on temperature difference, flow rate of the fluids.

In addition to the easy-to-clean plates regular checks on gaskets, seals are necessary. If a Zhuoli plate type heat exchanger is installed, not allowed any leaks. It is equally essential to monitor the fluid flow, temperature within these systems. This ensures the best possible heat exchanger efficiency. Critical to performance for any device is the material used in building it. Most vape kits are constructed from durable materials. These include stainless steel or titanium.

We're committed ongoing technological advancement research and development. We are committed to continuously making improvements Plate type heat exchanger performance and the customer experience. Our R and D team remains at the forefront of the field, bringing forward new technologies and products to meet changing needs of customers and accelerate the pace innovation in the industry.

With over 20 years' experience We have built up a wealth of expertise know-how in the industry of heat Plate type heat exchanger. professional team deeply understands technological developments market needs that allow us to provide accurate efficient custom solutions to ensure that each product is in line with the highest standards.

We make use the most advanced manufacturing equipment techniques ensure high-quality at every stage. Our {keyword}} developed to meet the highest standards quality, durability and performance.

We believe close cooperation our customers and offer a range of services. From needs analysis the Plate type heat exchanger of solutions to after-sales service, professional team follows each step the process to ensure the successful implementation of every project and generating the most value for our customers.