Corrosion Protection Techniques

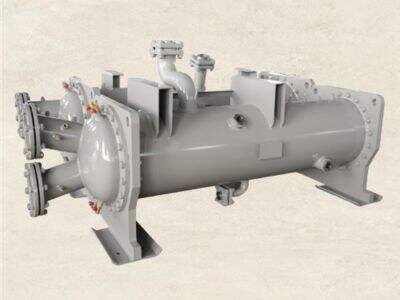

The last step is understanding why corrosion protection for refrigeration systems in marine environments is so important to maintain the health and welfare of this equipment. Rust & corrosion: Rust is a type of corrosion, and simply speaking, it is the damages on metal surfaces due to water and salt which cause rust and deterioration. The risk of corrosion is especially high in marine environments as rotary compressor refrigeration system are exposed to moisture and salty air every day. Corrosion can wear away at equipment without the necessary protection, which translates into even more expensive breakdowns and replacements.

Industrial Refrigeration Corrosion Prevention

The Innovative Coatings and Materials Solution to Combat It Many companies like Zhuoli pay ongoing research and development efforts leading protective measures from corrosion of refrigeration equipment. They extend the life of refrigeration pressure vessels and reduce breakdown risk by coating equipment with advanced protective coatings and corrosion-resistant materials. These new ideas offer a way to keep equipment running in otherwise-systematically brutal industrial environments that aggressively corrode.

Properly Cleaning to Prevent Any Damages

Another essential method to increase the longevity of refrigeration tools is by utilizing preventive servicing strategies. Conduct regular overhauls and cleanse to prevent damage to the corrosion as soon as possible. Regular maintenance and equipment cleaning can prevent corrosion from taking root in the first place, ultimately saving companies time and money. Such a proactive approach can save you time and money, be it avoiding costly repairs or downtime into the future.

With this whole system solution to corrosion protection, businesses can be sure that their refrigeration systems are kept in top condition, even when facing the rigors of the marine conditions. When companies take a proactive approach to reducing the chance for corrosion, those same expensive repairs and replacements can be bypassed by engineering entire systems optimized against it in the first place, resulting in both monetary savings as well as time saved over misadventures caused by unforeseeable failures.

Corrosion Protection

Aside from these, case studies such as that of successful corrosion protection solutions in various industrial refrigeration applications shows how paramount it is to invest quality on corrosion protection. Businesses can rely on a company like Zhuoli who have established themselves as experts in corrosion prevention to ensure that their most important refrigeration equipment remains functional and efficient for years. The above examples show how tangible returns can be when equipment performance and lifetime are extended through a proactive approach to corrosion protection.

Therefore, for companies who work in marine and industrial environments, corrosion protection should be one of the key points to take into account. Through recognizing the significance of preventing corrosion, experimenting with new coatings and materials, adopting preventative maintenance procedures, and using best practices for regulating corrosion risk, companies can have a more secure grip on protecting their refrigeration equipment – so that it will continue to provide efficient operation. With the help of an appropriate corrosion protection solution, they will be able to ensure the safety and reliability of their infrastructure, which will in turn lead to reduced repair costs and minimum downtime. Given the correct methods, companies can ensure their water cooled refrigeration condenser continue to run well and efficiently no matter how severe the conditions are.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

MK

MK

YI

YI

HY

HY

AZ

AZ

BN

BN

LO

LO

LA

LA

MY

MY

KK

KK