An Automated Solution in Pressure Vessel Safety: Why it Matters

Ever wonder how all those giant metal pressure vessels are made to keep us from going boom? Welding (you've seen a super-hot torch used to join pieces of metal) is an important aspect when building pressure vessels. Not all welding is done by humans, however. These systems are known as automation welding and the automatic system is an important factor in the strength of pressure vessels.

Investigating the science driving automatic welding in pressure vessel manufacture

Automated welding sounds like the kind of thing we see in sci-fi flicks but it is method used very real and beneficial way in many industries, pressure vessels have to be built using this technology for example. What is very interesting about it, is that are machines programmed to weld metal parts together in an efficient and precise manner. One such machine is the Zhuoli automated system that does weld using some of its most advanced software to ensure accuracy and precision. This technology can not only shorten the production cycle, but also greatly improve the quality and safety of pressure vessels.

Advantages of automated welding in improving pressure vessel reliability

There are numerous advantages of automating the welding process in be manufactured refrigeration pressure vessels. Reliability- This is the most important trait. Precision machine welding decreases the possibility for mistakes and low-quality welds due to their ability to be consistent as well. This resulted that a pressure vessel is made with automatic welding has very less probability of leaking or bursting which is safety for all people around. However, automated welding could potentially work faster than human welders seeing how many machines work quicker than their human counterparts which means more pressure vessels can be produced in less time to meet the rising demand for them.

Application of Automation in Welding for Pressure Vessels to Keep Them Intact

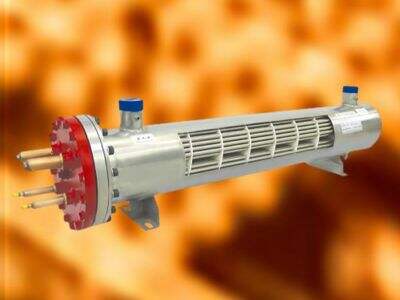

Integrity is king in the world of pressure vessels. What this means is they must be tough, robust and need to handle with high stress without fail. The role played by automated welding methods is fundamental to guarantee the integrity of heat exchanger vessel. Machines are able to make such strength due to careful control of the welding process, preventing any two metals from being temporarily kept together by imperfections in a weld that could otherwise weaken bridges, metal superstructures and more. As a result, it leads to more reliable and long-lasting vessels which means peace of mind for safety and productivity.

What the future holds for automated welding in pressure vessel safety and compliance

The pressures on the welds in a pressure vessel make that development even more crucial — and as technology advances, so does the role of automated welding. This is paving the way for increasingly advanced automated welding systems that can navigate highly complicated welds with minimal ease and increased precision. These will not only provide higher quality pressure vessels, they will also lead to a lower cost of production. Furthermore, automated welding continues to improve to fulfill the current safety norms and regulations that ensure heat exchanger pressure vessels live up to the contemporary requirements.

Automated welding is a significant part of the pressure vessels, which plays an important role in their safety and reliability. Using cutting-edge technology such as the advanced Zhuoli automated welding system allows manufacturers to fabricate pressure vessels that are both long-lasting and defect-free. Automated welding will remain crucial to ensuring the integrity and safety of pressure vessels into the future for us all. Therefore, the next time you are in front of a very high-pressure vessel, remember that behind it you have automatic welding doing its thing in order to guarantee your safety.

Table of Contents

- An Automated Solution in Pressure Vessel Safety: Why it Matters

- Investigating the science driving automatic welding in pressure vessel manufacture

- Advantages of automated welding in improving pressure vessel reliability

- Application of Automation in Welding for Pressure Vessels to Keep Them Intact

- What the future holds for automated welding in pressure vessel safety and compliance

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

MK

MK

YI

YI

HY

HY

AZ

AZ

BN

BN

LO

LO

LA

LA

MY

MY

KK

KK