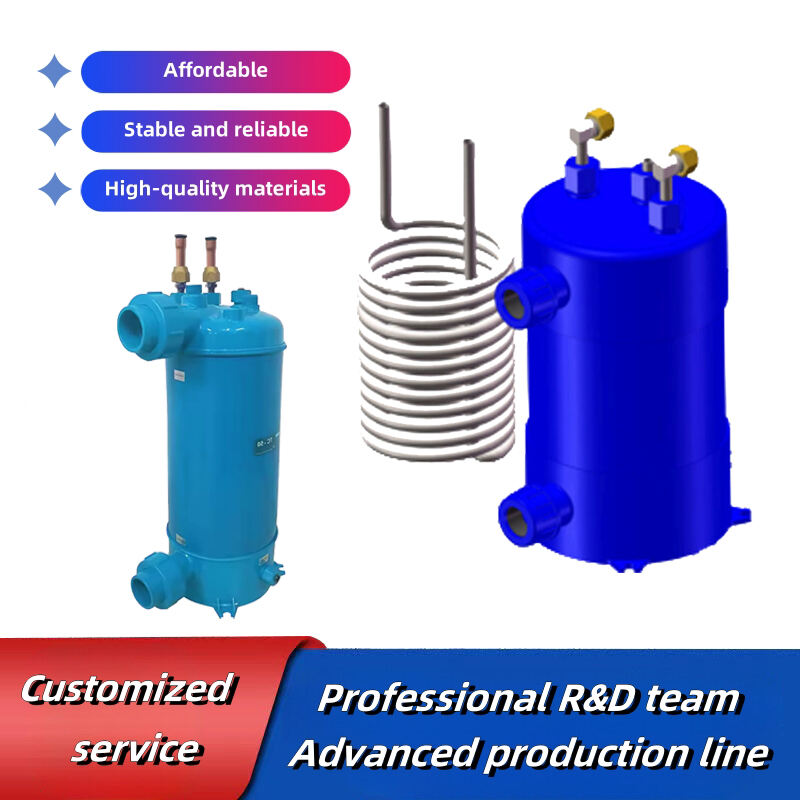

The shell and tube condensers are a specific element in multiple areas such as refrigeration, air conditioning or other fields that need heat exchange to be improved. These devices are a common choice among various industries as they have been known for their durability and reliability.

Traditionally, shell and tube condenser development has previously focused on improved energy efficiency with recent enhancements in the technology over 13 years. The new form of systems are having some revolutionary features combined with small tubes, which not only keep the energy resources conserves but also enhance the overall performance to a great extent.

The operation of shell or tube condensers has to pass the security regulation as it is the most important thing. Safety must also be taken into account to avoid accidents and some models are even equipped with built-in safety valves that provide an additional protection.

A shell and tube condenser is easy to use, but you will need some basic information and operating tips if it is required. It needs regular and timely maintenance which is required to extend the life of condenser, however safety rules are also important with efficiency so it should be used an efficient high quality condenser in order for productivity and Security.

Food production, medicine and a lot of other industries require the kind of very precise temperature control that only shell-and-tube condensers can provide. They allow for the rapid transfer of heat and are vital in manufacturing processes where temperature control is critical.

On the other hand, shell and tube condensers are used to cool liquids in an indirect way on secondary systems, which makes them essential for refrigeration chemical processing HVAC etc due to their higher heat transfer efficiency. They are best suited for extreme industrial setups where high pressure and temperature is common.

New advancements in shell and tube condenser technology revolve mainly around energy efficiency. The compressor variable speed is used to considerably reduce the energy for this purpose introduces manufacturers cutting-edge technologies. Although specialized models exist featuring a variety of tubes that promote both high and low heat exchange rates to the benefit of numerous sustainable industries.

Safety is of the utmost importance when working with a shell and tube condenser. Guidelines and hot safetyProtocol are Ignored Some models cooler are even loaded with security valves and temperature sensors to make the use much safer.

The key to a shell and tube condenser is that the entire spparatus will function effectively through proper utilization. Being in compliance of manufacturer guidelines, on top of winder maintenance schedules and responsible system management. The use of condensers made by the best-in-classmanufacturer makes it beneficial as maximum performance is guaranteed.

Ultimately, shell and tube condensers cannot be overlooked when it comes to maintaining thermal balance in industries and prove to be a crucial avenue for purposes of heat exchange or cooling The exceptional characteristics that these valves have, as well incredible performance and high efficiency rates are making them vital parts of industrial machinery installed in processes like surface finishing when precise temperature control is required beside the effective heat transfer.

EN

EN

AR

AR

HR

HR

CS

CS

DA

DA

NL

NL

FI

FI

FR

FR

DE

DE

EL

EL

HI

HI

IT

IT

JA

JA

KO

KO

PL

PL

PT

PT

RO

RO

RU

RU

ES

ES

TL

TL

IW

IW

ID

ID

LV

LV

SL

SL

UK

UK

VI

VI

HU

HU

TH

TH

TR

TR

MS

MS

GA

GA

MK

MK

YI

YI

HY

HY

AZ

AZ

BN

BN

LO

LO

LA

LA

MY

MY

KK

KK