Water and air cooled machines are essential to make the indoor atmosphere of a building cool, pleasant for breathing. Although functioning in different ways / can vary, the ultimate purpose of both is to cool air. A condenser - a key component inside these machines which aids in the cooling process. Air cooled machines vs water cooledIts important to know the difference between water and air crucial.

Water cooled -- these require water to cool the air in a building. They are quite effective in cooling large structures like schools or offices. In contrast, stand alone air cooled machines utilize the ambient air to cool and work in a completely different manner. The other type machines can do well but the water cooled machine has an advantage some players find preferable in that they are quieter. As a result, you will hear significantly less noise from them and that can be great in the light version.

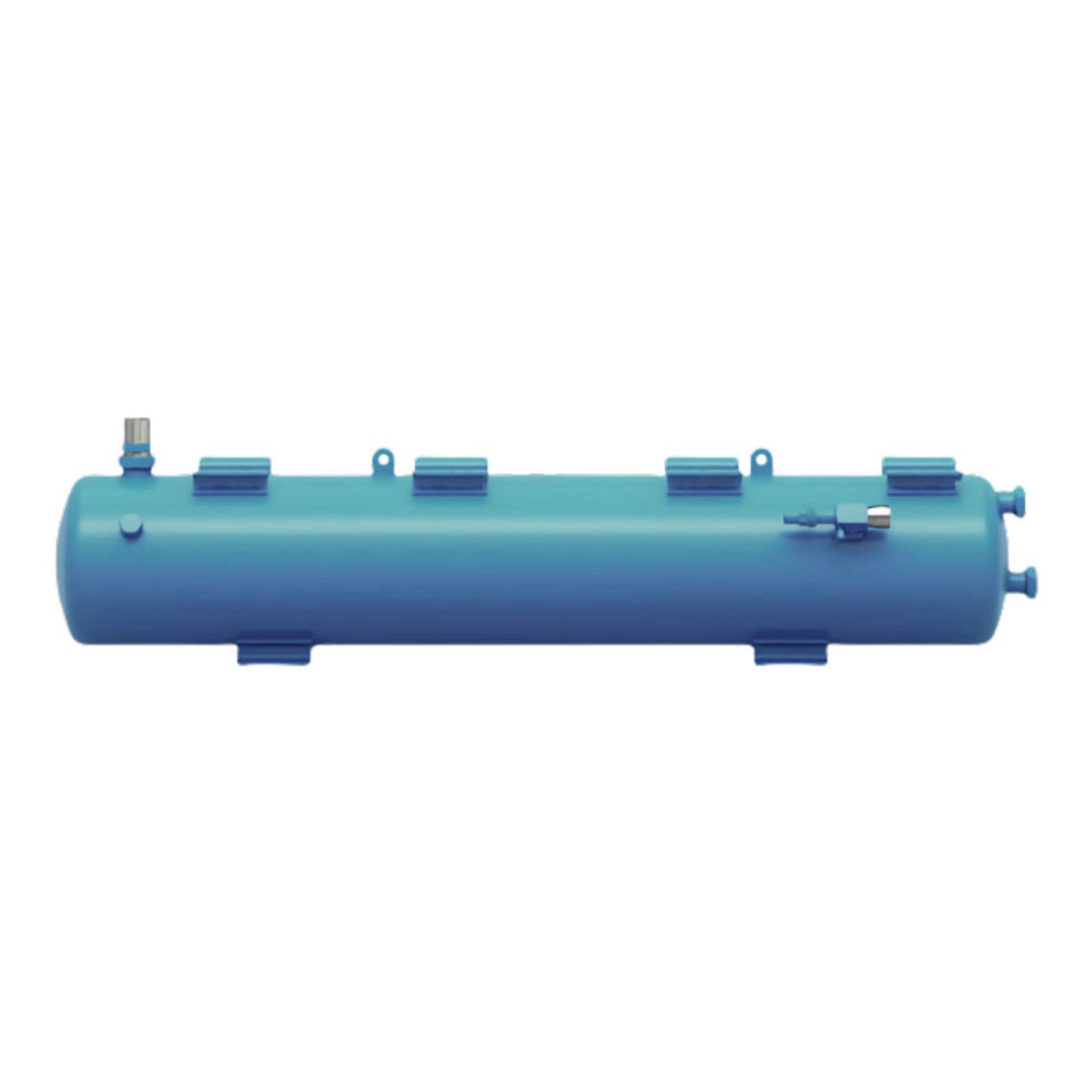

Cooling the item within these condensers is very effective for water cooled condensers. The best part about these machines is their low noise-level, while they are doing the work as well. This is very beneficial in environments with a demand for peace and quiet. Space Saving: Water cooled machines are generally popular because they require less space in a building compared to air-cooled machines. This can be a huge positive when in tight quarters or within dense urban settings. However, water cooled machines have their disadvantages too. This is something that might cost you more to integrate because it has a special pipeline that needs the water flow. This requires you to invest more money in the beginning. This can also be a challenge because the water is cooled by a part of the system called The Tower, which ics where when it was finished we had to place.

A water cooled (later) condenser is a good place to save not only great but smart money and also use the same tower which might be useful for plantation of you some trees. This then enables the cooling tower to recycle water, taking one lot of water and cycling it (endlessly) into a liquid-to-vapor state as no fresh drinking-water resource here trickles in from source every couple hours when condenser must be cooled. It is a money saver plus an eco-friendly practice which helps in water conservation too, that makes it really important.

For larger HVAC (Heating, Ventilation and Air Conditioning ) systems water cooled condensers are usually the ideal selection. This is because they are better at cooling the air compared to air cooled units. After all, large buildings need air to be cooled quickly and with a high capacity. Water cooled machines are also more compact and take up less space in a building. When you have a huge building that needs lots of coolingarea is important.

Ensure that you have a professional to clean your air cooled or water cool condenser in order for it works nicely. When the machine is cleaned, it prevents dirt and debris from piling up which may lead to your arrest of functioning. Equally, it should likewise be met by switching off the unit during disconnecting in a clean-up or upkeep job. This way no accident happens which is a good practice. Ultimately, be sure to handle it quickly if the landline does go down. The cause of Rectification-Take care. which will keep your machine working for longFullYear and you can work fine too

We have more than 20 years of water cooled and air cooled condenser in the field have developed a wealth of knowledge and expertise. Our team professionals are adept at keeping up the latest technology and trends in market. We offer accurate and effective solutions ensure that our products comply with the highest standards.

We believe in close cooperation our customers offer comprehensive services. From needs analysis solution design to after-sales support Our team experts will guide you each step ensure a smooth water cooled and air cooled condenser of every project, resulting in the greatest value for our clients.

We are dedicated to our constant advancement research and development, innovation increasing the water cooled and air cooled condenser of our products and customer experience. Our R and D department at the forefront of industry innovation in developing cutting-edge technology products that address evolving customer demands and drive industry progress.

We make use of most advanced manufacturing equipment techniques to ensure high-quality at every stage. {keyword}} rigorous quality-control process, our products have highest standards of performance, durability, reliability, meeting the demands of different challenging scenarios of application.