In essence, the two phase heat exchangers work in a way that alters the temperature of fluids by taking it from one fluid to another. In layman's terms, these are just machines used to cool or heat circulating liquids and gases. Two phase: They are called so due to the two different phases of matter exchanging heat. One might be a gas and the other liquid for example. In these instances, the heat exchanger serves alright to move between two stages which it cools the gas and warms its surround liquid stage (or otherwise), as you securities after.

Two phase heat exchanger advantages:Advantages of two slanting exchanges are more effective:this can save costs. They are used in countless industries, and we simply do not have the time to cover any but a few of them...]but sectors such as automotive [PG1 for Volkswagen award!], chemical, pharmaceutical...and many more[.... they would likely be mixed with other materials that transport heat between phases]. This heat exchangers has some other benefits also they prevent the over usage of energy which is a very important advantage. These avoid any energy loss that could arise when fluids are heated or cooled inadequately, allowing for control over fluid temperature.

One of these factors is the fit, form and function (FFF) of the heat exchanger - including tube length, diameter or fin pitch to aid better transfer between any two working fluids. Material selection is the next most crucial part. The pressure and temperature differences that occur must be confronted by the heat exchangers - these are made out materials capable of resisting such an environment.

Applications like manufacturing, energy production and even appliances are using dual phase heat exchangers. They are used in industries to cool down the temperatures of liquids and gases inorder for manufacturing processes On the other hand, crossflow heat exchangers are used in energy systems to control fluid temperatures that operate inside power generation plants and differ types of amenities where efficiency performance is important. Nuclear reactors use two phase heat exchangers to maintain the temperature of coolant fluids, and geothermal power plants use them for from highly pressured hot subterranean fluid as often separated in a neutralizer balance-tapped feed system between reboiler/condenser heart-exchanging streams.

Miniaturization of Two Phase Heat Exchangers The originality in the work consists of using microscale heat exchange to provide better performance with a smaller size compared to conventional two phase systems. Another way of development followed is integration of high performance materials such as nano material in heat exchanger improvement along the research. So, as an example - it will soon use research programs to convert a full spectrum of light-absorbing and reflecting materials nodules into heat exchangers that could redefine the more basic ways we control fluid temperature though solar energy.

In conclusion the two phase heat exchangers is critical technology for many industries to control fluid temps as an overall. Knowing how they work, advantages as well as improvements will help further fine tune these machines in order to achieve more efficiency and minimum energy wastage.

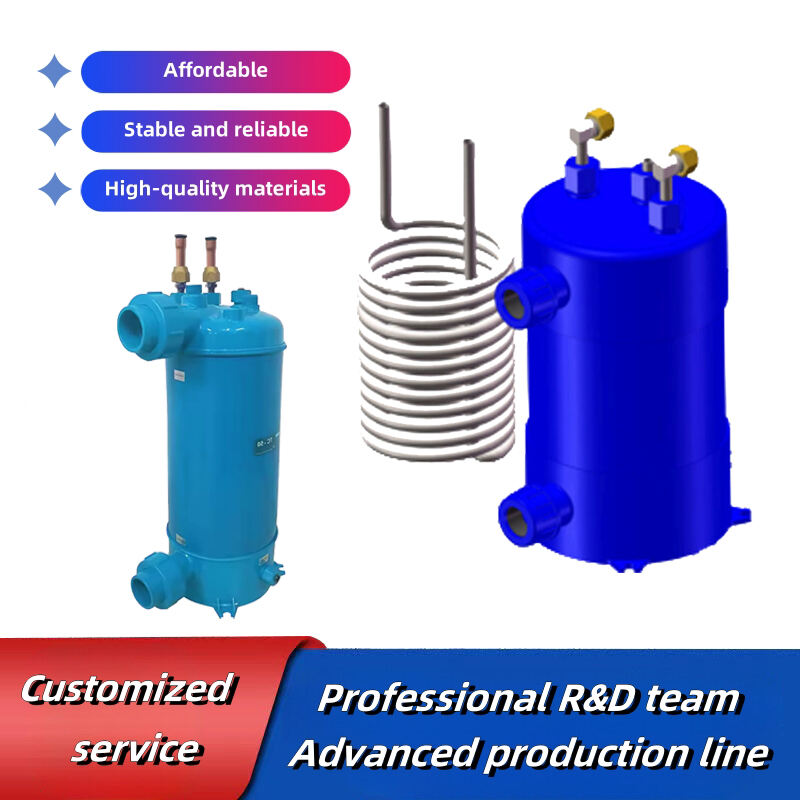

We are committed in our ongoing innovation, research development and two phase heat exchanger the performance our products and customer service. Our R and D department at the forefront of innovation industry, creating breakthrough technology and products address changing customer needs and help drive industry progress.

With more than 20 years' experience in industry and expertise, we have gained rich knowledge technology in the area of heat exchangers. Our two phase heat exchanger team fully comprehends technological developments market needs and provides precise and efficient tailored solutions to make sure that every product is in line with highest standards.

We utilize latest production methods equipment, guaranteeing excellence each stage. By implementing a rigorous quality-control system, {keyword}} achieve top-of-the-line performance, durability dependability, which meet the requirements a variety of intricate scenarios of application.

We believe close cooperation our customers and offer a range of services. From needs analysis the two phase heat exchanger of solutions to after-sales service, professional team follows each step the process to ensure the successful implementation of every project and generating the most value for our customers.