The steam condenser is a big metal box that helps cool down the stream, turning it into water. Home / Science & Engineering Articles / Steam Condenser Heat Exchangers Explained - What are they and Why do you care?

Steam Condenser - A Heat Exchanger Design and Its Operation Walk-through

Steam condenser heat exchanger design of a Steam Condenser is really easy in which steam flowing out has the next temperature stays within it and metal pipes at such an area are current that calm household steam blows from spherical cold water box on to this condensate. It is designed to cool the steam so that it can be refed into a reactor's system. Preheating (precooling) of this switching is transferred to the cold water circulating inside the condenser. Naipu pumps the cold water out to recycle and cool down separately before returning it for reuse, also.

Steam Condenser Heat Exchangers have a number of advantages to offer. Such machines are power saving and also efficient water fall utilization in the industrial sector. By doing so, they save fuel and decreases emission of dangerous gas into the atmosphere. Except, you know, the hundreds of dollars companies save in overheard costs

An example of where Steam Condenser Heat Exchangers can be used: Chemical plants Power stations etc Its job is thaT of recycling wasted energy and saving precious resources. These devices also find use in pasteurizing liquids (e.g. milk, fruit juice) within the food & beverage industry?

Due process should be taken in maintaining the efficiency of Steam Condenser Heat Exchangers. These machines should be cleaned on a regular basis in order to have them operate well. Clean heat exchanger polys, replace vanes that are looking a little old and check for leaks often which will help keep it as healthy at 1115 hours.

To increase the efficiency, one would have to properly manage water level in a condenser and seal it well enough making it leak-proof. Keeping the steam temps consistent is also important, as well as keeping that condenser water cold. Additionally, the optimal installation method of heat exchanger and its isolation should be endeavoured to keep it from generating or transmitting excessive heating.

Furthermore, as mentioned cc earlier: keep your steam condenser heat exchanger well maintained and troubleshoot properly to assure proper working. Scale Buildup is a term used to describe the time in which minerals and other debris become stuck on units.

A layer of scale will eventually form on the heat exchanger causing it to function less efficiently, reducing performance and therefore increasing running costs. To prevent scaling the water must be treated. There are water treatment processes which utilize chemicals and one can feed issue free water to the heat exchanger an hence ternish it free operation.

Fouling; The third main problem with Steam Condenser Heat Exchangers is when particles and containments stick to the edges of exchanger. Unnecessary sparking fouling Waste of resources and increased infrastructure costs due to performance_DOWN_CSV FILE After this cleaning use a variety of chemical treatment in some such solution catalysts and other reagents, these can be dosed for cathodic protection chemicals specifically used to clean the previously mentioned dirt but also soluble oil from stainless steel or similar black surfaces if that helps prevent it.

With the above mentioned characteristics, a very known example of such innovation is to develop Steam Condenser Heat Exchangers. They are also constantly working on new technology to enhance the efficiency and effectiveness. Such as the use of ceramic coatings on heat exchanger tubes, that reduce scale and fouling formation resulting in an increase in efficiency.

For additional technological advancements, smart sensors can also be used that offer real-time steam and water temperatures providing fast alerts for operators when they are irregular. By this proactive approach thinking the operators can fix things before they become worse which will reduce their operating costs as well as down-time.

Last but not least, I am expecting that these Steam Condenser Heat Exchanger are going to aid the industries by running with energy saving and pollution soot control without fail meant for affordable machineries as well hence in-respective high efficient. Contribute to regular maintenance practices, troubleshoot system issues and implement the latest technologies help these machines last longer in peak performance mode.

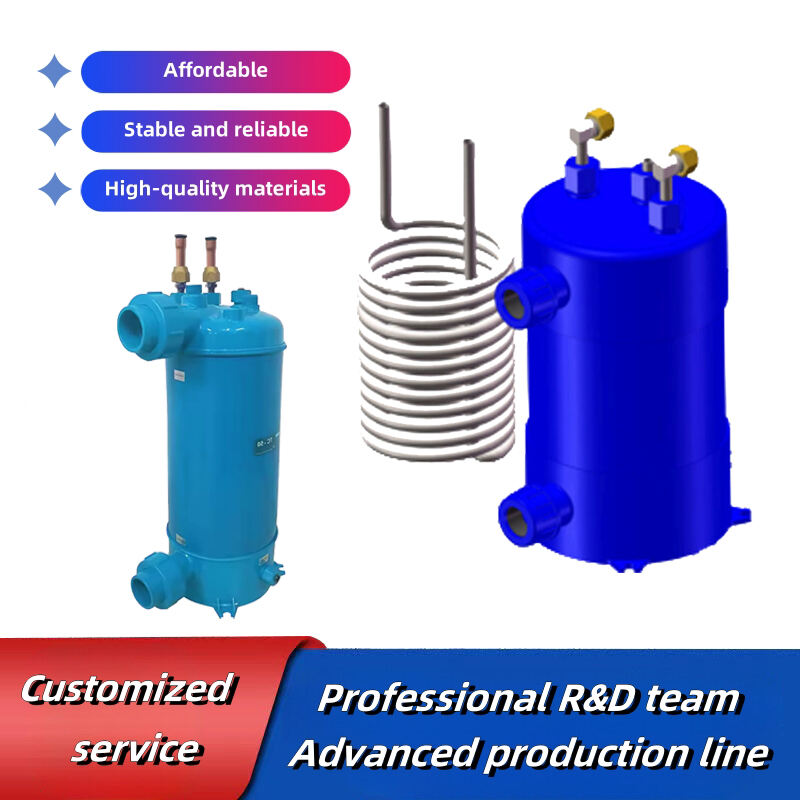

We make use of most advanced manufacturing equipment techniques to ensure high-quality at every stage. {keyword}} rigorous quality-control process, our products have highest standards of performance, durability, reliability, meeting the demands of different challenging scenarios of application.

We're committed to constant steam condenser heat exchanger, research development and making products more efficient the customer experience. Our R and D team remains at forefront of industry, creating breakthrough technologies products that can meet the demands of customers the changing times and drive industry progress.

With more than 20 years of experience and expertise, have gained rich knowledge technology in the industry of heat exchangers. staff of experts is knowledgeable about most recent technological steam condenser heat exchanger and trends. We offer high-quality efficient solutions to ensure that our products comply with the highest standards.

We appreciate close co-operation with customers and provide a wide range of services. Our team experts will walk through every step starting from needs steam condenser heat exchanger through design of a solution support after sales in order maximize value each customer.