Stainless steel heat exchangers are parabolic devices designed for the sole purpose of transferring thermal energy from one form to another. So, in this article we will be talking about Stainless steel Heat Exchangers and also explore more on different aspects such as features & applications of the same.

Resistantness to high temp: this is the most important benefit connected with stainless steel heat exchangers and may be essential for its desired function. This renders them important for applications with such high heat-relevant processes e.g chemicals and petrochemicals. In addition to this, the ability of their resistance to rust and corrosion is what makes them stand out from other materials but also guarantees durability.

The stainless steel heat exchanger landscape has evolved rapidly over time. This led to advancements such as brazed plate heat exchanger technology. By collectively brazing large numbers of thin, small plates, the heat exchangers became far more efficient and much longer-lasting than previous types. Furthermore, the innovation has led to a small size which allows for antenna use also in tight spaces without making compromises on performance.

Stainless steel heat exchanger safety precautions:

Maintaining cleanliness-Stainless steel heat exchangers need to be cleansed and maintained well on regular basis simply because corrosion can make them useless in your inside walls of home as well as it may lead into safety hazards. To ensure that these equipment can perform in a safe manner, installation and operation of the attachment shall be according to manufacturer's procedures.

Applications of Stainless Steel Heat Exchangers:

The stainless steel heat exchangers are much flexible in nature, they have wide usage applicability all over the terminals of the world. The third category falls out in dozens of apps: nearly all home based hot-water heating, air-conditioning systems along with commercial building suites and homes-reliant on hexmedia; processes energized regularly across meals making a sector food right through residing plus tanning using your petrochemical sectors please chemical_; you could certainly have the possibility as well sugar established raids around their electrical classification. Moreover regardless of refrigeration units, power generation too since it shows the flexibility in application.

Aug 23, 2016 While using a stainless steel heat exchanger is pretty straight forward it will only work as effectively if you follow these basic steps. This can be done once you have installed the unit properly and linked it up to an appropriate system, but i am jumping ahead of myself : from installing your heat exchanger for about a time frame after putting in use, is what we really oughtta do to find out how well it works.

The stainless steel heat exchanger is a very delicate machine and it needs some maintenance practices to get an improved performance efficiency with long-lasting potential. To keep it working, selecting the better means in recovery as well destruction. When in need of a stainless steel heat exchanger it is recommended to goonly you should only buy from reputable suppliers so that this purchase gives the best results.

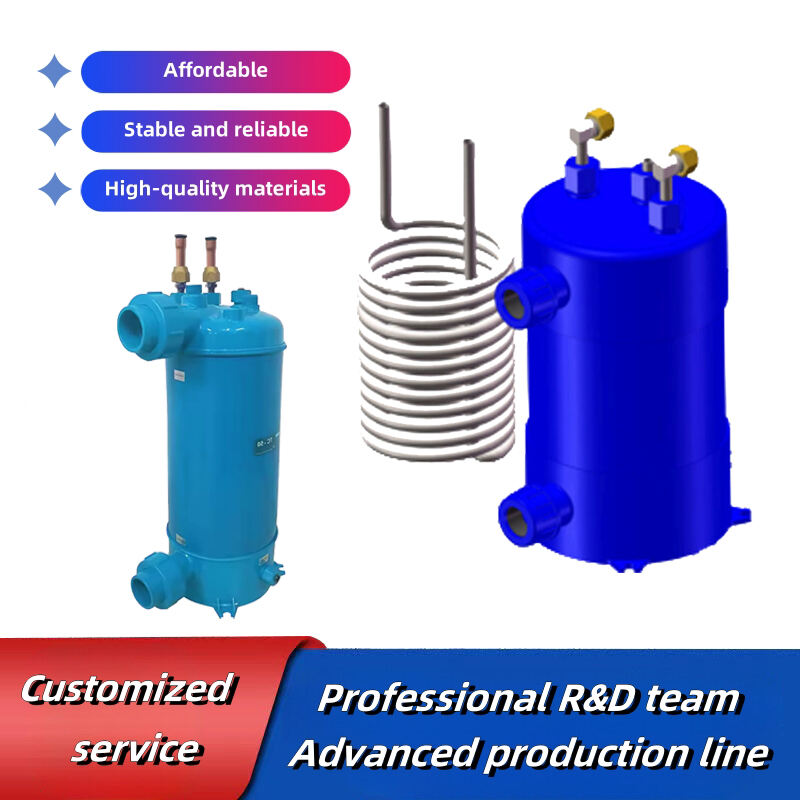

We are dedicated to our constant advancement research and development, innovation increasing the stainless steel heat exchanger of our products and customer experience. Our R and D department at the forefront of industry innovation in developing cutting-edge technology products that address evolving customer demands and drive industry progress.

We are committed close collaboration with our customers provide a wide range of services. Our stainless steel heat exchanger team guide you every step of the way starting needs analysis through the design of solution and support after sales to ensure maximum value for each client.

We {keyword}} most advanced manufacturing methods equipment to ensure excellence every stage. Our products are made exceed the highest standards in endurance, reliability performance.

With more than 20 years of experience and expertise, have gained rich knowledge technology in the industry of heat exchangers. staff of experts is knowledgeable about most recent technological stainless steel heat exchanger and trends. We offer high-quality efficient solutions to ensure that our products comply with the highest standards.

Stainless steel heat exchangers are used for a variety of industrial applications including chemical processing, oil and gas operations or food processing lines. These are located in buildings for commercial, and resindental places with limited space there can be no separate heating ventilation air conditioning system. Also used in power generation equipment such as nuclear control plants, geothermal planters and thermal stations are stainless steel heat exchangers to enable the transfer of great energy from a source application with higher temperatures at overall peak levels.

Stainless steel heat exchangers are similar to this just that they represent how well and good the general materials could perform only if. Stainless steel HEAT EXCHANGER is a trade-in of productivity meet safety as far as some industrial installations relevant here or there. The recent string of developments in technology has led to the creation of more slender, smaller-sized heat exchangers. As long as proper maintenance and good sellers are considered, there is no question that these tools will manage to be useful for years.