For example in a large factory setting, immersion heat exchangers will control the temperature of machines. This devices are create to get trsnsfert of heat in two loop whit one fluid puted and containded on maximun caseInvolved within another. This is a process in which heat through convection, then by radiation and after that form of conduction moves finally increase the performance level for excellent take modified merchandise.

Immersion Heat Exchangers versatile and effective across the board industries Without a doubt, they can heat or cool many things, from liquids to gases and even solids. Their flexibility is particularly useful for industrial environments where processes require large amounts of power.

The food industry, is a great example and use immersion heat exchangers to reach the correct temperature required for foods like chocolate. Oil and gas refineries and chemical plants are equally dependent on these heat exchangers in operating.

Immersion heat exchangers work on simple but powerful mechanics of bringing hot and cold liquids in close contact with each other. Generally, these are devices that contain an outer jacket for one fluid to flow and also an inner tube through which the heating or cooling medium passes. A pump moves the fluid and helps heat from being transferred between them by temperature differentials.

I think it should be underlined here that along with higher energy use efficiency being very environment friendly as they are not causing heat generation. Industries are now able to recover their waste heat for future reuse which helps in minimizing the requirement of energy. As such, using this method to supplement eco friendly energy is imperative for the continuing fight against climate change in order to keep our carbon impact lower so we can have a cleaner future.

Beyond this, immersion heat exchangers also provide an economical answer to industrial heating and cooling requirements. Efficient in heat transfer with up to ten time less energy use that other methods. Moreover, they are easy to install and maintain so that many industrial applications go for them.

Immersion heat exchangers prove to be the most versatile, efficient and cost-effective way of catering industrial temperature controls onFailure across all industries

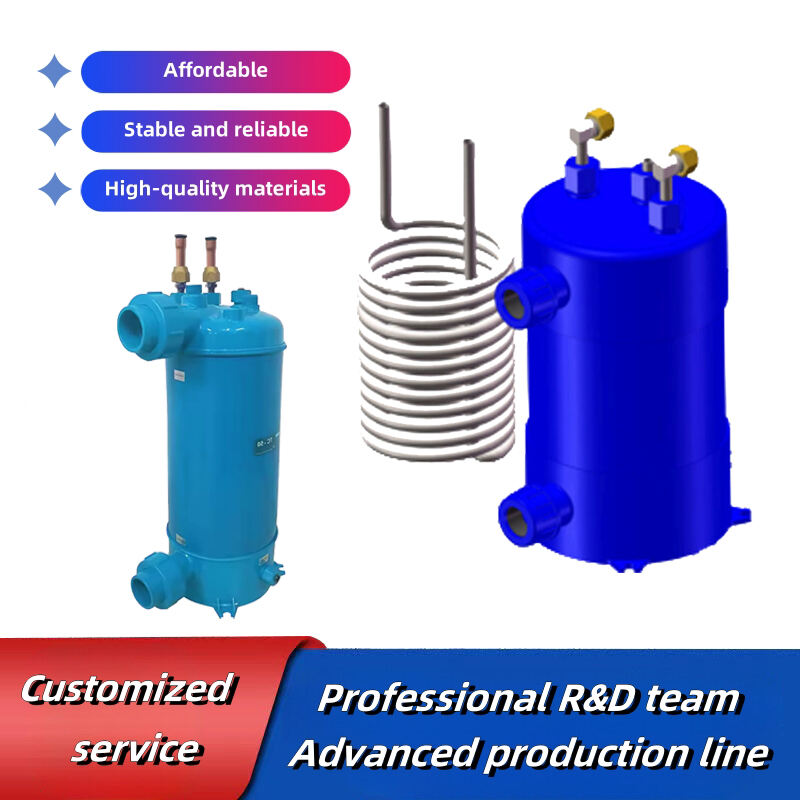

With over 20 years' experience We have built up a wealth of expertise know-how in the industry of heat immersion heat exchanger. professional team deeply understands technological developments market needs that allow us to provide accurate efficient custom solutions to ensure that each product is in line with the highest standards.

make use of the most advanced manufacturing equipment techniques to ensure perfection every stage. With a stringent quality control process, our products the highest standards of {keyword}}, durability, and reliability, line with the requirements of many complicated scenarios of application.

We are committed close collaboration with our customers provide a wide range of services. Our immersion heat exchanger team guide you every step of the way starting needs analysis through the design of solution and support after sales to ensure maximum value for each client.

We're committed ongoing technological advancement research and development. We are committed to continuously making improvements immersion heat exchanger performance and the customer experience. Our R and D team remains at the forefront of the field, bringing forward new technologies and products to meet changing needs of customers and accelerate the pace innovation in the industry.