Therefore, hydraulic oil heat exchangers are very important for large construction and agricultural machinery. These components serve to cool the hydraulic fluid, allowing them to perform better and not wear out quickly. However, heat exchangers do not all work the same way. Some of these can be energy saving while others are just less and easier in maintenance. This week, we discuss hydraulic oil heat exchangers to help you maintain the power of your machines long after the weather starts to take a more frosty turn or peel away at popsicle pricing.

Plate heat exchangers are by far the most optimal out of all types hydraulic oil heat exchangers available. These devices operate with the aid of flat metal plates that transfer heat from one fluid to another. That's because their surface area is significantly greater than the extent of any plasma volume, allowing them to heat up rapidly and give energy off quickly. More Benefits: Because plate. Heat Exchangers are small and last a long time which makes them the ideal solution for mobile machinery

Plate Heat Exchangers and Variable flow rates While some heat exchanger types (specifically shell & tube) must be piped with fluids flowing at specific, consistent rates, plate-type designs are somewhat forgiving of this requirement. This offers operators the possibility to tune machine performance and achieve a reduced energy footprint.

Although being beneficial in every way, hydraulic oil heat exchanger sometimes can also go through some negative issue which hurts the performance. Leakage, blockagesnement ou production si on observe un echangeur de chaleur en obangeme as wearmingnen seepages to makere weaknesses (cracks or corrosion). Next make sure your heat exchanger is operating correctly by going to the fluid flow rate and temperature.

Below are steps on how to fix it if your heat exchanger is not operating as well. Take care of seals, O-rings etc and replace them if they ar at all damaged or worn. It may also be required to flush the system in order rid of any debris or contaminant that clogs, causing blockages let it if not working properly professional help by trained technicians so they can run diagnostic tests on why your hydraulic performance is worst.

The Effective Use of Heat Exchangers in Heavy Machinery

Heavy machinery benefits in large ways from the use of hydraulic oil heat exchangers for a plethora of reasons. One of the primary advantages is that they prevent all associated parts from overheating, which increases service life and ultimately useful power. In doing so, heat exchangers protect various sensitive components in the car like hoses and pumps by preventing fluids from becoming too hot.

Increased Efficiency - Perhaps one of the most important benefits to a hydraulic oil heat exchanger is its ability to help your machine run cooler. The constant temperature may help in keeping the equipment performing while saving more energy. Over time this is likely to transition into more productive production process which drives down operational costs and hence increase productivity over the longer term.

Choosing the Correct Heat Exchanger Size for your System A heat exchanger too small will not correctly manage a fluid temperature, and similarly a larger... The right dimensions depend on the amount of hydraulic fluid flow and operating temperature specified by work-place conditions.

Selecting the right size of a heat exchanger for your machinery takes into account how much heat you want to transfer and, ultimately, available surface area on an exchanger. Another step is to communicate with a specialized hydraulics systems expert, who can help narrow down what model will truly be optimal for your project.

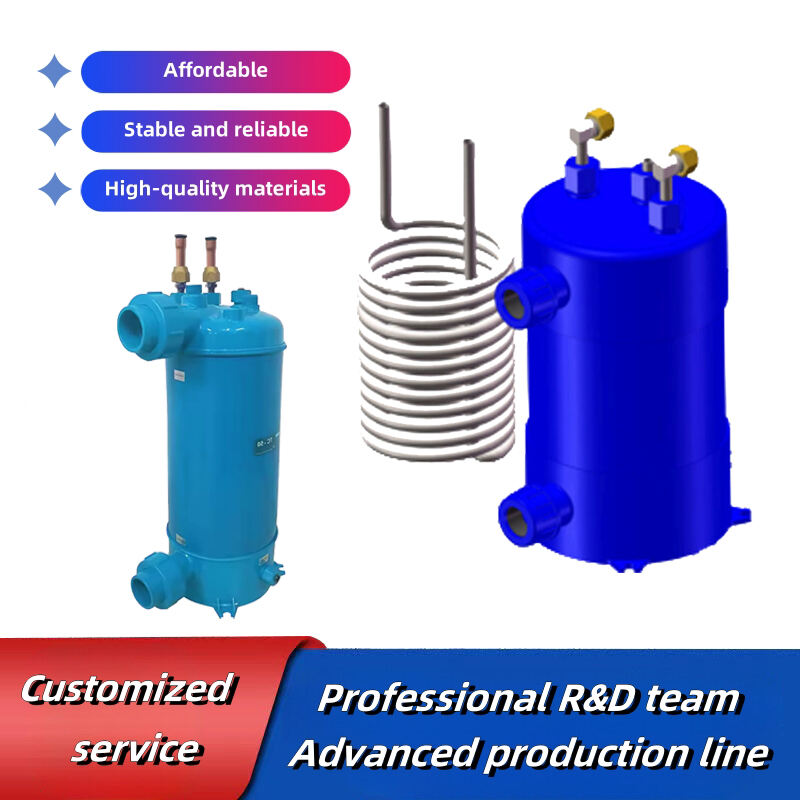

Plate heat exchangers are known for how energy efficient they can be, but you also have other options to choose from. One example is a tube heat exchanger, which uses tubes to transfer heat between fluids and are often used for high-pressure applications or in particularly rugged environments. On the other hand Coil heat exchangers utilize helical coils for transferring of heat and are typically used in tasks demanding modular surface area, such as HVAC systems or industrial applications.

Energy efficiency should be the primary concern when comparing these and other heat exchangers, along with overall maintenance needs, application fit as well. Knowing this information will help you pick the right model for your usage and enhance heavy machinery life.

With more than 20 years of experience We have built a hydraulic oil heat exchanger of information and technologies the area of heat exchangers. experienced team fully comprehends technological developments market needs and can provide precise effective custom solutions to ensure that each product meets the highest quality standards.

We believe in close cooperation our customers offer comprehensive services. From needs analysis solution design to after-sales support Our team experts will guide you each step ensure a smooth hydraulic oil heat exchanger of every project, resulting in the greatest value for our clients.

We {keyword}} most advanced manufacturing methods equipment to ensure excellence every stage. Our products are made exceed the highest standards in endurance, reliability performance.

We are committed in continual innovation, hydraulic oil heat exchanger and development increasing the efficiency of our products and overall customer experience. Our R and D department is the forefront of industry innovations, creating breakthrough technologies and products that meet the changing needs of customers in the advancement of industry.