If you are looking for high quality gas liquid separator, then contact KVR Process. Gas-liquid separators play a very important role in getting natural gas ready for us to use it as our energy source today. Natural gas that we take from deep underground is usually mixed up with other liquids, such as oil and water. If we do not remove these liquids away, they can clog up pipes in the ‘machines’ and wreck havoc upon them as well as cause harm to those that live around us (our environment!).

The function of Gas liquid Separators is more involved than simply separating gas from liquids. They are also instrumental in machine protection and safety for everyone! Gases can damage such essential equipment like compressors, and pumps when they come in contact with the liquid. Not only are these repairs expensive, but they can also cause a lot of downtime and safety issues for the workers.

When it comes to choosing the perfect gas liquid separator for your work, you need to be precise. Let us find out some of the separators are being here to serve their purpose as all they need spectrum kind a technology There is so much types and based on that we get specific separator for particular requirement. This is essential because choosing the suitable separator can dramatically affect the efficiency of all.

Some separators are excellent at separating out all liquids in bulk, while others can easily separate even just small amounts. Certain separators are best suited for high pressure, while some others cater to lower pressures. Carefully selecting the appropriate separator for your use can help alleviate all of this; making it work better, faster.

Incidentally, there´s constantly the improvements in gas-liquid separator technology and that couldn´t be a better way to end this information than with good news! The separated gas and liquids we are able to obtain now through new technology is easier done than ever before. It means that we can do our job better and by the way, save a little carbon.

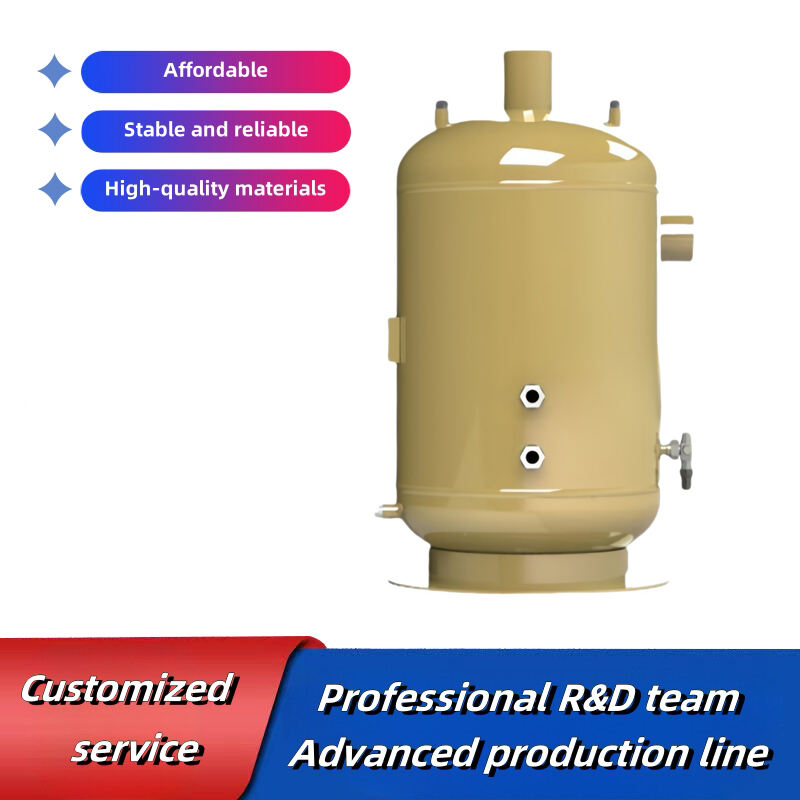

For example, some more recent separators are composed of stronger materials which can withstand higher clamping forces and those that may exert greater physical demands on the separator itself This material is virtually indestructible, making it much longer lasting and far superior in terms of usage. This is really significant because it signifies that we can count on them for a long time without having to replace them frequently.

Computer-based modeling of gas and liquid flow has also seen numerous advancements, leading to better insights. Researchers can learn a lot about how these materials behave by using special computer programs. This understanding allows them to develop superior separators that can operate most effectively while adding increased efficiency.

We believe close co-operation with our clients, providing complete support services. From needs analysis and solutions gas liquid separator after-sales services our team of professionals follows through every step ensure the smooth implementation of every project, resulting in the greatest value for clients.

We are committed to continuous technological innovation, as well as research and development that constantly increasing the quality of products and improving customer service. Our R and D team on top of the industry, developing breakthrough gas liquid separator products that meet the ever-changing needs of our customers and help drive advancement of industry.

With more than 20 years of experience and expertise, have gained rich knowledge technology in the industry of heat exchangers. staff of experts is knowledgeable about most recent technological gas liquid separator and trends. We offer high-quality efficient solutions to ensure that our products comply with the highest standards.

We make use the most advanced manufacturing equipment techniques ensure high-quality at every stage. Our {keyword}} developed to meet the highest standards quality, durability and performance.