Have you ever considered the design possibilities of a corrugated heat exchanger? These amazing machines are responsible for heating or cooling of liquids and gases in countless industries. To help you dig deeper into the world of corrugated plate heat exchangers and learn more about THEIR advantages, applications, design requirements that must be taken care of during installation & maintenance as well as some typical issues users may encounter.

Corrugated heat exchangers offer numerous advantages: efficiency with certain media, very compact dimensions and robust design for high-pressure use. These wonderful abilities have allowed them to be used in so many industries, including chemical plants or power generating facilities; as well as on how food is made.

In chemical industry these heat exchangers help in heating or cooling of hazardous liquids like acids, Which is quite tough work and can only be easily done by Corrugated Metal Heat Exchanger. These devices help in cooling of steam generated by power sources (nuclear or fossil fuel) in the generation plants. Likewise, heat exchangers are indispensable for the temperature adjustment of milk and juices etc in food companies.

When designing a corrugated heat exchanger, one must carefully consider several tendencies. For example, the materials used must have high-temperature durability and corrosion resistance. In addition, the fowling should produce minimum pressure drop between fluids flowing for proper performance.

The maintenance of an offspecification corrugated heat exchanger is very important. Clean regularly to prevent build-ups of fouling that can directly affect the efficiency of your machine.

There are many types, shapes and sizes of corrugated heat exchangers. These are devices that consist of two parallel plates to contain the fluids and they have corrugations which produce turbulence, increasing the efficiency of heat transfer.

The fluids flow on either side of the plates, permitting heat to move from one fluid into another. While the fluids remain separate, heat is exchanged through plate chromes.

Construction Of A Heat Exchanger Should Be Done With High-Quality Material And Must Installed Properly For Long Life Span Vigilance must be maintained to detect and address ordinary problems such fouling, scaling, or corrosion that might decrease the machine's effectiveness.

Hence it is proved that corrugated heat Exchanger is a required asset in several industries. These devices are so small and sturdy that they can be used to filter high-pressure fluids as emerging contaminants in industrial applications. Key considerations to remember during the design or service of a heat exchanger are that it should regularly be cleaned and have high-grade materials for an efficient running throughout its life.

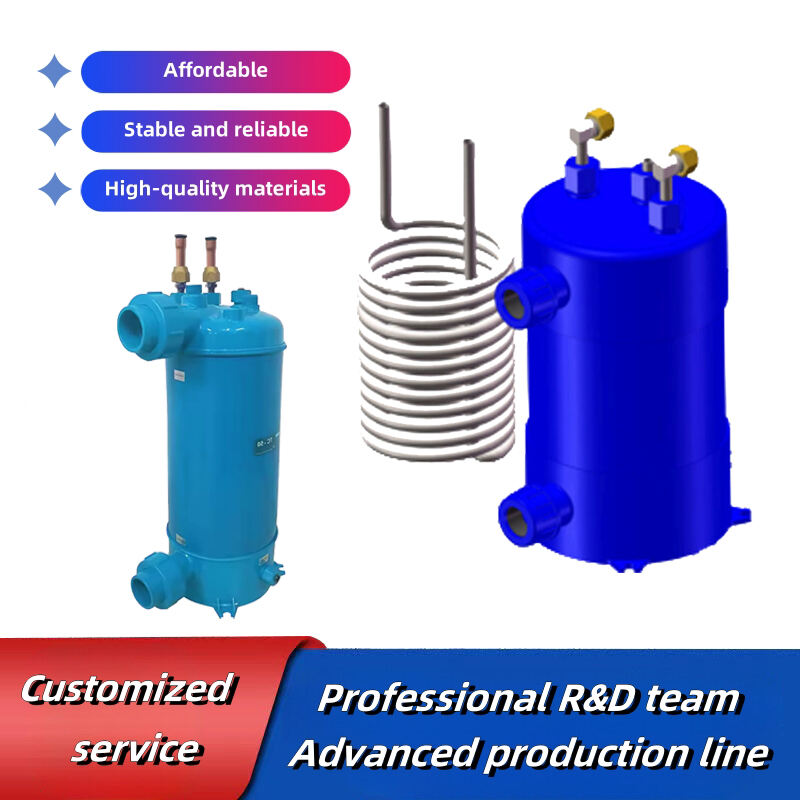

We're committed ongoing technological advancement research and development. We are committed to continuously making improvements corrugated heat exchanger performance and the customer experience. Our R and D team remains at the forefront of the field, bringing forward new technologies and products to meet changing needs of customers and accelerate the pace innovation in the industry.

We believe in close cooperation with customers and offer a range of services. Our expert team be there to guide customers through every step from need analysis to design of a solution and support after sales, create maximum corrugated heat exchanger for each client.

We use most {keyword}} manufacturing techniques equipment, ensuring excellence every stage. Our products made to exceed the highest standards performance, durability and reliability.

We have more 20 years of experience in industry and have accumulated a wealth corrugated heat exchanger and technologies. Our experienced team fully comprehends market demands technological trends, provides precise and efficient customized solutions to ensure each product is in line with the highest standards.