Heat exchangers are vital to our everyday life as they help move heat from one place to another. This is very important to make many things run in the way we expect them. For example, in cars, heat exchangers are used to control the engine temperature and avoid overheating. Similarly, air dryers rely on a heat exchanger to improve their efficiency by extracting the hot compressed air and use it to preheat incoming airflow.

Freedom to be more energy efficient: takes advantage of an air dryer heat exchanger These heat exchangers take the heat that is produced when compressed air cools in the dryer and use it to warm up incoming cold, wet air instead of requiring more work from your compressor. As a result, this translates to energy-consuming expense reductions for users.

The wide application of air dryers includes products used in food and beverage, pharmaceuticals as well auto sectors. These commercial grade applications depend on heat exchanger technology to provide this vital function of air drying. The passage of heat from the compressed air to the inlet air is additionally promoted through warmth exchanger technology which increases efficiency a long way above that possible with simply one drying method. In addition, there is a large range of air dryer heat exchanger types available in the market having different pros and cons.

Advanced heat exchanger technology has transformed the air drying process, dramatically improving both efficiency and reliability. Heat exchangers are some of the most efficient and low cost heat transfer devices, when combined with new materials and designs it has never been easier to apply all types of industrial applications as well. With so many benefits, these advancements can help businesses not only to save money on energy costs but also serve the purpose of environmental conservation by reducing their use of electricity.

The heat exchanger is an important component of the air dryer which needs to be maintained correctly so that it may retain its shape and work efficiently for a long time. Regular dryer maintenance will ensure that your device works well and save you all the trouble for potential future problems. Regular cleaning, leak inspections and timeous swapping of parts that have undergone wear-and-tear can result in your air dryer lasting much longer. Adhering to these maintenance guidelines will improve the performance of your dryer which will in turn save you money and make an environmental difference.

Therefore, heat exchangers are necessary in many industries to provide energy-saving solutions and maximum functionality. Additionally, knowing the importance of different heat exchangers and how to keep them operating properly through maintenance routines are crucial processes for getting your air dryer functioning at peak performance. This in turn will help you to save the costs, prolong your equipment life and of course environment as well.

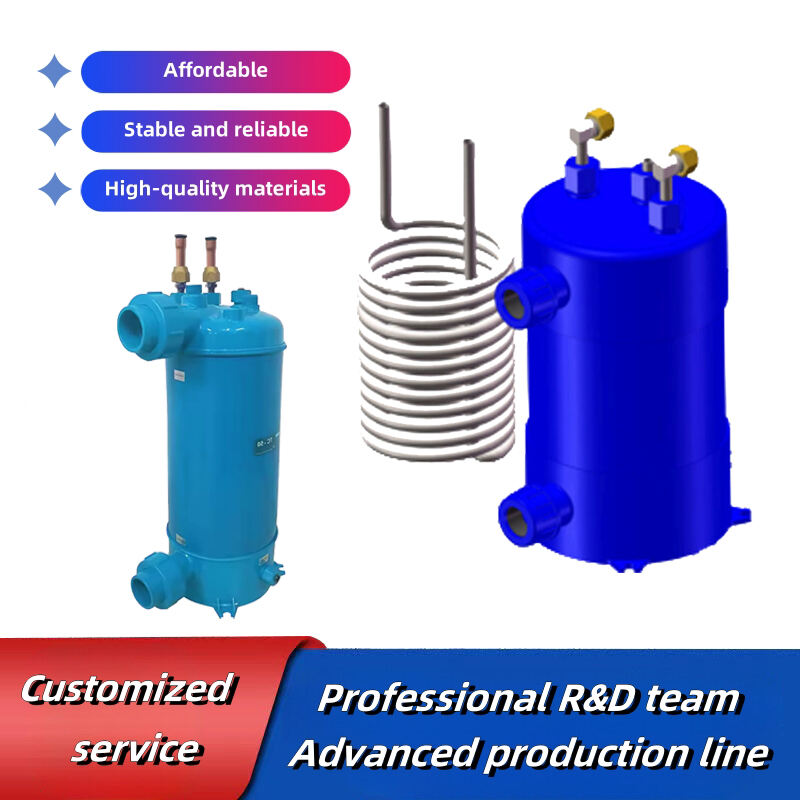

We make use of most advanced manufacturing equipment techniques to ensure high-quality at every stage. {keyword}} rigorous quality-control process, our products have highest standards of performance, durability, reliability, meeting the demands of different challenging scenarios of application.

We more than 20 years working in field and have accumulated vast knowledge technology. Our team air dryer heat exchanger are adept at keeping up with latest technological advancements and trends. We offer precise and efficient solutions that ensure our products are in line with the highest standards.

We appreciate close co-operation with customers and provide a wide range of services. Our team experts will walk through every step starting from needs air dryer heat exchanger through design of a solution support after sales in order maximize value each customer.

We're committed air dryer heat exchanger technological advancement and research and development, continuously improving product performance customer experience. Our R and D team stays the forefront of the industry, creating breakthrough technologies and products that meet demands of customers in changing times and accelerate the pace of innovation in the industry.