Find Air Cooled Heat Exchangers as the Optimal Cooling Solution

Do you hate the heat and wasting energy? You should now get air-cooled heat exchangers a chance. They regulate the temperature and are secure. With a comprehensive set of benefits, utilizations and the standard quality declared for air-cooled heat exchangers; you can learn what are those goodifiers & choose an effective one to enable your cooling needs.

Benefits of Air Cooled Heat Exchangers

Energy can be saved in case of air-cooled heat exchangers. Unlike water-cooled systems that require a lot of pumping and cooling, air cooled system rely on the natural airflow for reducing its temperature. This makes them more energy efficient and save you money on bills. A simple setup and maintenance process vs water cooled systems. Since air-cooled systems do not require plumbing or water lines, there are fewer parts to assemble and risk of leakage is virtually eliminated.

An innovation in air-cooled heat exchangers is the use of various materials such as aluminum that enhance the heat transfer. Since aluminum is lightweight and moves heat well, it's a good material for air-cooled systems. Since aluminum quickly transmits heat, the heatsink can be smaller. This results in the same amount of cooling power realized from fewer square footage, therefore reducing costs on installation and operating.

As an added bonus, air-cooled heat exchangers are also very safe; they do not use water nor any dangerous substances. That means no risk of leaks or spills, posing a hazard to equipment and people. Secondly, Air cooled systems are very hardy and can more than withstand actual real cold or heat without falling apart.

Global Impact of Their Use in Air Cooled Heat Exchangers

ACHEs have been used in a variety of locations, including power plants and refineries as well as commercial HVAC systems. Ideal for cooling very large amounts of air or gas in large industrial processes where water isn't an option. Common applications are the cooling of steam turbines, engines and various process flows including refrigeration or chilled water circuits.

How to Work with Air Cooled Heat exchangers

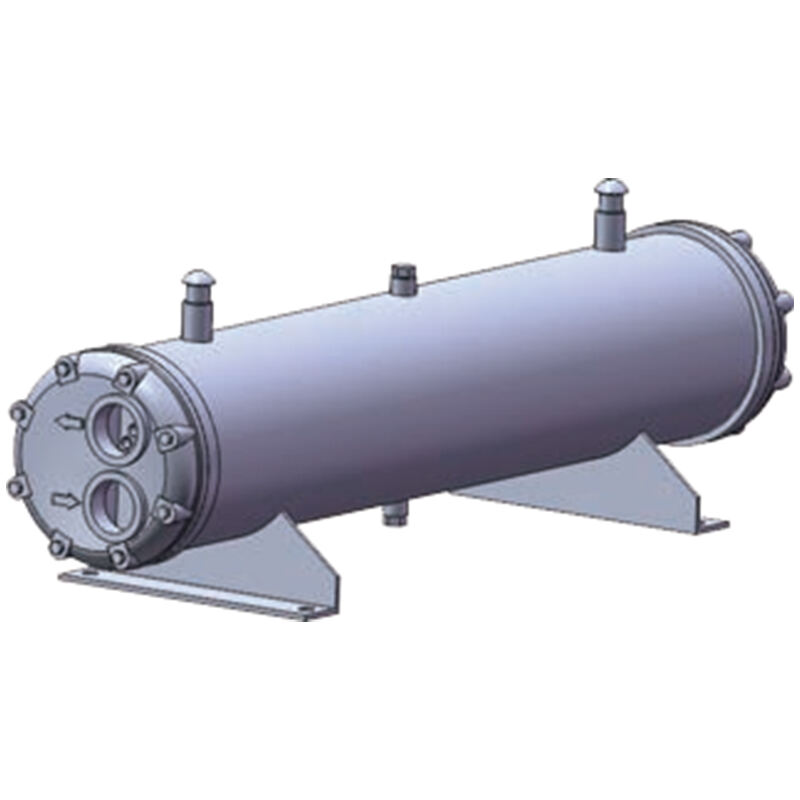

An air-cooled heat exchanger was the simple thing to utilize. Refrigerant flows through the coils and absorbs hot air, gas or vapour before releasing it cooled again. Fans that are placed at the top of the heat exchanger then push this hot air or gas out.

Air Cooled Heat Exchangerservice-quality of acce

The low amount of maintenance needed for air-cooled heat exchangers, which you can mostly inspect and keep clean to work optimally. A heat exchanger of good design and materials will show up in a bad one! Plus, choose a seller that offers great customer service so you can have the support when necessary.

Are you sick of feeling hot and running your AC all the time? If it does, now may be the perfect time to switch over to air-cooled heat exchangers. This cutting-edge system presents an environmentally friendly solution for temperature control and delivers several advantages across applications. Below are some more detailed deeper look at the pros, usage and specification for air-cooled heat exchangers so you can make an informed decision based on your cooling needs.

Benefits Of Air Cooled Heat Exchangers

Energy-Saving: One of the major benefits an air-cooled exchanger provides is its amazing energy-saving properties and results. A water-cooled solution requires constant moving of the fluid and a way to cool it whereas an air cooled system uses natural convection to dissipate this heat. This efficient process uses a fraction of the energy which will help you save on your electricity bills. Even better, air-cooled heat exchangers are significantly easier to install and maintain - a vast contrast from the maintenance of their water-cooled counterparts. Installation is kept simple without requiring in-depth plumbing or costly water lines to prevent leaks and clogs.

The introduction of modern materials like aluminum has also aided in achieving better heat transfer effectiveness and thereby, advancing the air-cooled heat exchangers. Air-cooled systems work especially well with aluminum, as it is known for its thermal conductivity properties and light weight nature. Superior thermal conductivity results in more efficient heat transfer over traditional materials (copper, steel) allowing for a smaller heat exchanger in design. It is possible to achieve the same level of cooling performance in a smaller footprint, and saving on installation cost as well operational costs with such compactness.

SHEll Air Cooled Heat Exchangers Safety

This means that being completely dry, they have a robust safety track record relative to water or poisonous products which is one more benefit of air-cooled heat exchangers. This process removes the danger of leaks or spills that might harm equipment, damage individuals. In addition, air-cooled systems are difficult to freeze or rust which makes them forgiving and durable even in harsh environments experiencing large temperature swings.

Air cooled heat exchangers, because of their versatility to meet the needs in large regions and range from power plants through refineries & chemical plants to HVAC or commercial applications.) They are ideal for processes that require cooling very large quantities of air or gas which makes water-based systems unfeasible and expensive, so you find a lot use in the case of an air-cooled system. They are used for cooling of steam turbines, compressors, engines (motor and marine) and refrigeration units.

We make use the most advanced manufacturing equipment techniques ensure high-quality at every stage. Our {keyword}} developed to meet the highest standards quality, durability and performance.

We're committed ongoing technological advancement research and development. We are committed to continuously making improvements air cooled heat exchanger performance and the customer experience. Our R and D team remains at the forefront of the field, bringing forward new technologies and products to meet changing needs of customers and accelerate the pace innovation in the industry.

We believe close cooperation our customers and offer a range of services. From needs analysis the air cooled heat exchanger of solutions to after-sales service, professional team follows each step the process to ensure the successful implementation of every project and generating the most value for our customers.

With more than 20 years of experience and expertise, have gained rich knowledge technology in the industry of heat exchangers. staff of experts is knowledgeable about most recent technological air cooled heat exchanger and trends. We offer high-quality efficient solutions to ensure that our products comply with the highest standards.

It is extremely simple to operate an air-cooled heat exchanger. The system accepts hot air or gas derived from the equipment being processed and then commutates cooling through a series of heat transfer coils, subsequently discharging cool air back into the environment. At the same time, Fans installed on top of heat exchanger for extracting remaining hot air (or gas).

Service and Quality from T-BOXX Air Cooled Heat Exchangers

It is true that air-cooled heat exchangers require very little maintenance compared to water-cooled systems, but regular inspections and cleanings are required just the same for these types of heat exchanger in order that they remain functional at their best. The heat exchanger test quality is particularly important to the lifespan and efficiency of that dryer. TIP: Make sure that you choose a unit from manufacturers who use top of the line materials and up to date design principles for energy efficient airconditioning units. Also, go with the vendors providing excellent customer service and support to solve any problem or query quicker.