It is genuinely hilarious the technology in a magnetic levitation heat exchangers. They get components to levitate and move without touching any other part - Magnetism! This interesting feature not just helps with longer life span of these fixtures but also cuts the necessity of frequent repairs. What makes them even better is that these machines are small and lightweight, so they can be used in many different scenarios where conventional heat exchangers would not work. What separates them from other reactors is their significant effects on industrial processes and the deployment of renewable energy.

Their operation involves moving a thin liquid film over either heated or cooled surfaces, using centrifugal forces. Which reduces the energy required to successfully move and or spin, using magnetics at key places helps keep this spinning motion precise with zero contact needed for fast heat transfer. Extremely effective and clean technology, which is an attractive selling point for companies looking to reduce their environmental impact and overhead.

Apart from the above advantages of saving energy, isothermal performance and fast response, magnetic levitation heat exchangers are also highly efficient in maintaining required temperatures no matter how much the load changes during operation. These components are ideal for pharmaceutical or food production applications where cleanliness is paramount due to the non-contact of moving objects in this design. Moreover, these systems can also be tailored to suit individual operational requirements thereby making them more versatile and practical.

ApplicationsThe uses of these incredible machines are endless and valuable. Example in chemical manufacturing may help to enhanced reaction efficiency and reduce energy consumption especially in high temperature processes. Green energy facilities, particularly those extracting geothermal resources have been gaining from the magnetic levitation heat exchangers higher the efficiency of overall system by improved waste recovery. In addition, such heat exchangers have helped save energy in large buildings as well as data centers by tuning the cooling systems.

There are many and wonderful success stories connected to magnetic levitation heat exchangers. This includes, at a petrochemical plant which integrated these advanced systems into their operations they were able to say goodbye to energy prices and many of the costs associated with it as well. Such examples emphasize the game-changing possibilities this technology has to offer as it pertains energy management and environmental sustainability.

In summary, magnetic levitation heat exchangers represent a blend of modern technology and eco-conservancy. Services and industries that are a part of what the future holds, will almost certainly have to make use of these machines at least in its basic form over time if it is to do right by energy savings ecological responsibility. One successful implementation after another, magnetic levitation heat exchangers are only cementing their future role as catalyzers for a cleaner...

At the heart of these heat exchangers lies the innovative application of magnetic levitation. By suspending the rotating elements without physical contact, friction and wear are dramatically reduced, leading to enhanced longevity and minimal maintenance requirements. This technology not only improves system reliability but also paves the way for more compact and lightweight designs, enabling their integration into spaces where conventional heat exchangers would be impractical or inefficient. By pushing the boundaries of traditional design, MLCFFHEs are transforming industries from petrochemical processing to renewable energy systems.

The underlying science of MLCFFHEs combines principles of fluid dynamics, magnetism, and thermodynamics. A thin film of process fluid is propelled by centrifugal force along the heated or cooled surface, maximizing heat transfer efficiency due to the increased surface area contact. Simultaneously, magnetic fields precisely control the rotation of the central element, maintaining a stable and precise levitation that eliminates the need for mechanical bearings. This unique setup ensures rapid heat transfer while minimizing energy losses, resulting in a highly efficient heat exchange process.

One of the most compelling aspects of MLCFFHEs is their potential for significant energy savings. By reducing friction and optimizing heat transfer, they operate at lower power consumption rates compared to conventional heat exchangers. This directly translates into reduced carbon footprints and operational costs, making them an environmentally friendly choice. Furthermore, the enhanced efficiency supports industries in meeting their sustainability targets and contributes to global efforts against climate change. In essence, MLCFFHEs embody the perfect blend of economic viability and ecological responsibility.

Beyond energy efficiency, MLCFFHEs offer superior process performance. The uniform and continuous falling film ensures excellent temperature control and rapid response to process changes, vital in applications where precise temperature regulation is critical. Additionally, the elimination of mechanical bearings reduces the risk of contamination, making them ideal for use in pharmaceuticals, food processing, and other hygiene-sensitive industries. The inherent flexibility of these systems allows for customization to suit specific process requirements, further enhancing their value proposition.

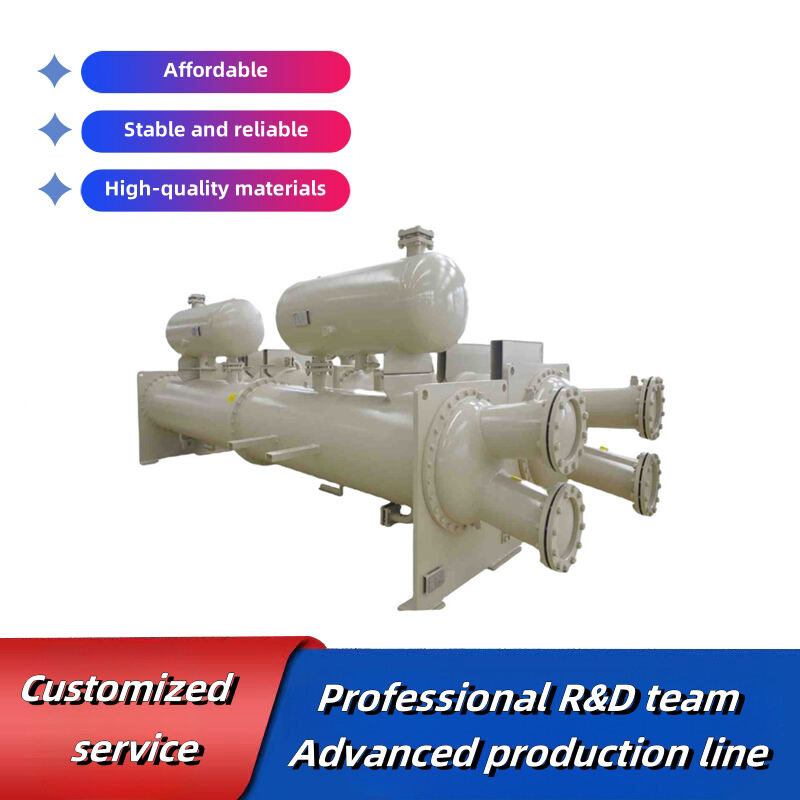

We value close cusMagnetic levitation centrifugal falling film heat exchanger omer cooperation provide comprehensive services. From needs analysis solutions design after-sales services Our team experts will guide you each step of the process ensure smooth execution of every project and generating the most value for our customers.

With over 20 years' experience We have built up a wealth of expertise know-how in the industry of heat Magnetic levitation centrifugal falling film heat exchanger. professional team deeply understands technological developments market needs that allow us to provide accurate efficient custom solutions to ensure that each product is in line with the highest standards.

We utilize latest production methods equipment, guaranteeing excellence each stage. By implementing a rigorous quality-control system, {keyword}} achieve top-of-the-line performance, durability dependability, which meet the requirements a variety of intricate scenarios of application.

We are dedicated to ongoing innovation, research and development and making products more efficient customer service. Our R and D department at the forefront of industry Magnetic levitation centrifugal falling film heat exchanger in developing cutting-edge technologies products that meet ever-changing customer requirements drive industry progress.

The practical implications of MLCFFHEs are widespread and diverse. In the chemical industry, they have proven effective in high-temperature reactions, improving yield and reducing energy consumption. Renewable energy plants, particularly those harnessing geothermal resources, employ these heat exchangers to optimize heat recovery processes, thereby increasing overall system efficiency. Moreover, in HVAC systems, MLCFFHEs contribute to more efficient cooling towers and chillers, reducing energy demands in large-scale buildings and data centers. Success stories abound, including a notable instance where a petrochemical plant integrated MLCFFHEs, achieving a 20% reduction in energy consumption and substantial cost savings over just a few years.

In conclusion, magnetic levitation centrifugal falling film heat exchangers exemplify the marriage of advanced technology and sustainability goals. As we continue to push the frontiers of innovation, these systems will undoubtedly play a pivotal role in shaping a future where energy efficiency and environmental consciousness go hand in hand. With each successful application, MLCFFHEs affirm their position as game-changers in the quest for a greener, more efficient world.