The heat exchanger is central to any cooling system that needs the transfer of heat between two fluids. Wherein, a 1 shell2 tube pass heat exchanger is one type of particular kind of Heat Exchanger. This design features a shell housing two sets of tubes. The liquid passes via a set of pipes, then through another group so the heat can flow between both fluids more effectively.

A wide variety of applications use this type of heat exchanger including the chemical industry, HVAC systems and refrigeration as well. Therefore, these exchangers are used in the cooling or heating purpose even providing them with high profit and for those systems that need accuracy temperature.

Design and optimization are vital for a 1 shell, 2 tube pass heat exchanger in terms of improvements concerning its performance. Heat transfer efficiency is influenced by factors such as the size, shape of shell and tubes, materials used for construction (selection of material), flow rate etc. Engineers use computer simulations and experimental tests to optimize the design for a particular application in order to maximize efficiency.

High surface area tubes are one of the most efficient ways to enhance and augment heat transfer in a Heat Exchanger. Fins on the tubes can be employed to increase this surface area, increasing heat exchange efficiency without growing the overall size of your HX. Moreover, those materials with great thermal conductivity would accelerate the whole heat transfer.

Most of times to find the best style heat exchanger for an application a comparative analysis is carried out. Although 1 shell 2 tube pass heat exchangers perform well when the temperature of fluid is critical and there's a high difference in the temperatures, One should know that each type of heat exchanger has its own advantages as well as disadvantages.

Though they can handle high flow rates with little change in efficiency, 1 pass heat exchangers often are simply too large when there is a size constraint for the overall system. Any heat exchanger will be selected based on temperature ranges, flow rates, fluid properties (specific heat and thermal conductance), size restrictions or requirement to just name a few of these influences vs cost.

A heat exchanger is configured so as to have the right number and size of tubes for maximum efficiency. This entails a deep study of the application needs in addition to reviewing with how heat exchangers could be put up plus managed.

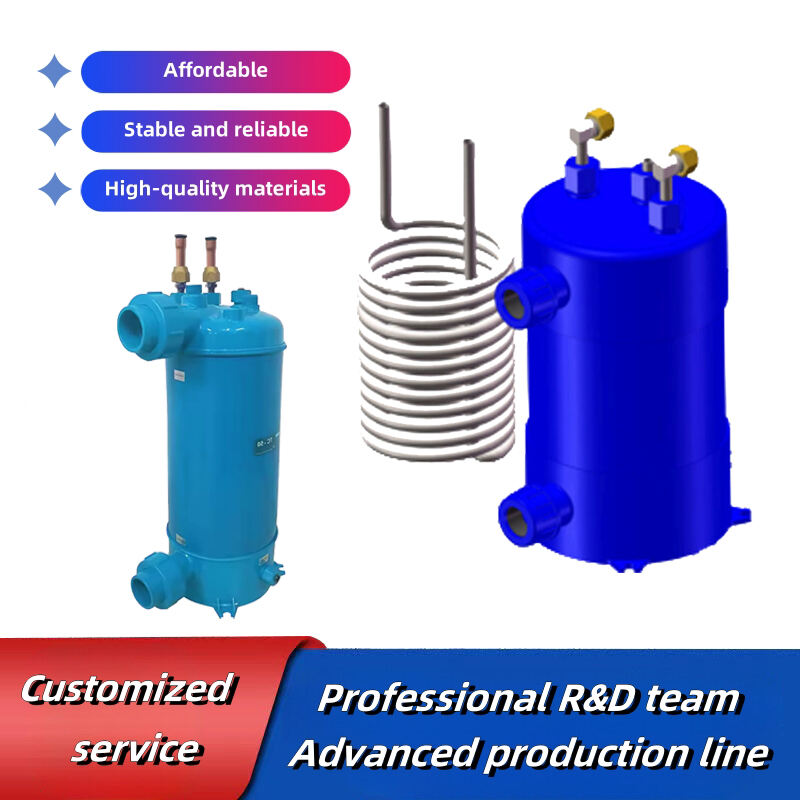

We're committed to constant 1 shell 2 tube pass heat exchanger, research development and making products more efficient the customer experience. Our R and D team remains at forefront of industry, creating breakthrough technologies products that can meet the demands of customers the changing times and drive industry progress.

We believe in close cooperation with customers and offer a range of services. Our expert team be there to guide customers through every step from need analysis to design of a solution and support after sales, create maximum 1 shell 2 tube pass heat exchanger for each client.

We make use of most advanced manufacturing equipment techniques to ensure high-quality at every stage. {keyword}} rigorous quality-control process, our products have highest standards of performance, durability, reliability, meeting the demands of different challenging scenarios of application.

We more than 20 years working in field and have accumulated vast knowledge technology. Our team 1 shell 2 tube pass heat exchanger are adept at keeping up with latest technological advancements and trends. We offer precise and efficient solutions that ensure our products are in line with the highest standards.